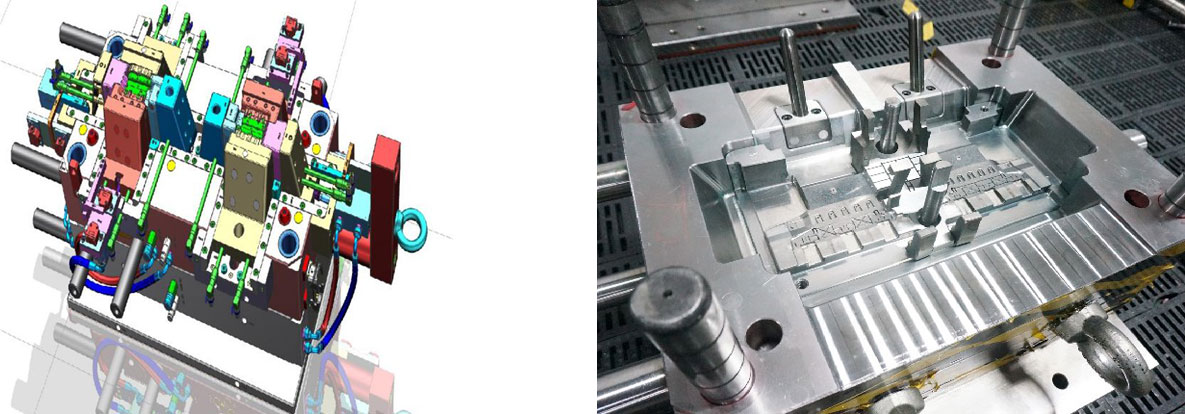

Tooling

At Omni we’re here to support you with a comprehensive Tooling capability. Whatever your needs we can assist you with Rapid, Prototype & Pre-Series Tooling, Low Volume Tooling or Production Tooling, along with a range of Tooling Support Services. From tool maintenance, refurbishment, modification or calibration we’ve got it covered for you.

Thanks to our long and established history, OMNI has acquired an extensive tooling capability backed up by a team of people, with a can-do attitude, who have the skills and technical knowledge you can rely on. We can provide you with tools up to 50 tons globally thanks our worldwide footprint. Wherever you are, you will find an OMNI partner ready to fulfill your expectations in term of innovation, responsiveness, price, lead time and quality.

OMNI works with a diverse range of clients from a variety of industry sectors. These include but are not limited to: Automotive, Transportation, Packaging, and Consumer Products.

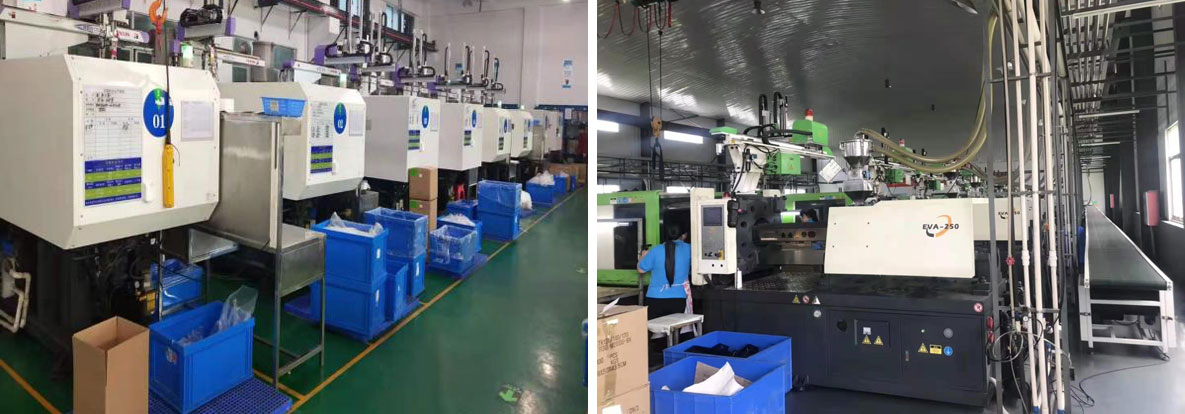

We’ve built up a considerable track record of supporting clients with our range of rapid tooling services along with our innovative technology concept which allows for large prototyping plastic components to be manufactured in low volumes in production materials.

OMNI is also able to provide you with LOW VOLUME TOOLS AND PRODUCTION TOOLS in different technologies to meet your needs.

Injection Tooling (in steel or in aluminum)

Precision, Multi Cavity, Twin Shot, Over Moulding Capability

SMC/BMC Moulds

RTM Moulds

Injection molding

Aluminium die casting tools

Pre-tension ® tooling technology

Hot forming tools

Filament winding tools

Composite tools

We are also able to support you with your more specific Tooling requirements, such as:

Tool maturation

Mobile laser welding service

Maintenance and tools modification

Industrial maintenance

CNC Machining

Tooling and Moulding Training.